Managing The Increasing Speed of Future Trends With A High-Speed Control System

The industrial automation industry is constantly accelerating, requiring manufacturing equipment that can operate with high accuracy at blistering speeds. This demand pushes for new control technology that delivers real-time performance and seamless integration. Many companies are turning to EtherCAT technology and advanced software from acontis, such as their EC-Master EtherCAT MainDevice and real-time hypervisors, to power their next-generation machinery.

The Role of EtherCAT in High-Performance Machinery

Modern manufacturing relies on highly synchronized motion. A single machine might contain hundreds of servo drives, sensors, and actuators that must communicate and act within microseconds of each other. This is where EtherCAT excels. Its "processing on the

fly" principle with data telegrams processing in hardware enables ultra-fast communication with minimal delay and zero jitter. This allows for accurate network-wide synchronization with sub-microsecond accuracy. The high data bandwidth of EtherCAT also supports the vast amount of sensor and process data that must be managed in real-time.

acontis: Experts for EtherCAT and real-time virtualization since more than 20 years

acontis technologies, based in Germany, has a leading position with its EtherCAT software portfolio and is known as a highly competent EtherCAT specialist. The company recognized the potential of EtherCAT early on, starting development on the EC-Master EtherCAT MainDevice software already in 2004. Since then, the EC-Master has been implemented in over 1.5 million controllers from hundreds Scalability: EtherCAT's flexible topology and features like Hot Connect allow scalable, dynamic device integration without reconfiguration, supporting evolving industrial needs.

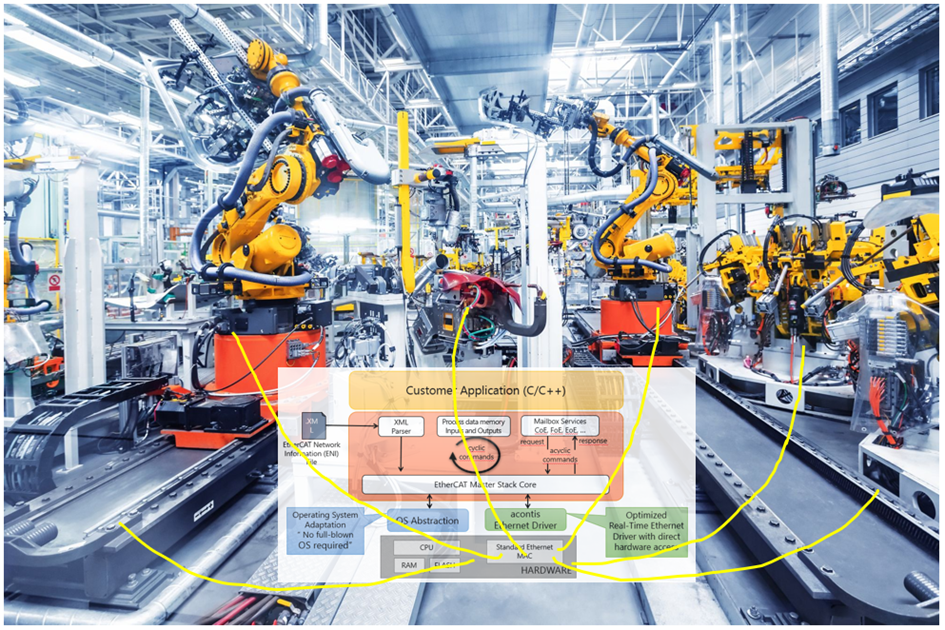

EC-Master: The Control Core used in thousands of high speed production machines

The acontis EC-Master is a robust, high-performance EtherCAT MainDevice stack for various platforms. The key benefit of EC-Master is its high-performance design that ensures deterministic behavior and low jitter, regardless of network size or complexity. It handles all aspects of the EtherCAT protocol, from network configuration and startup to runtime monitoring and diagnosis: This allows machine and controller developers to concentrate on their application logic rather than the intricacies of the fieldbus protocol. The EC-Master has a rich feature set, including support for distributed clocks and hot-connect functionality, which are essential for required accuracy, flexibility, and machine uptime.

Real-Time Virtualization: Combine flexibility with reliable hard-real-time operation.

Another challenge in machine design is the consolidation of system control blocks . Traditionally, a machine required separate hardware for the real-time motion controller, the HMI, and other non-real-time tasks like supervision and data-logging. The acontis RTOSVisor and Lxwin real-time hypervisor solutions address this by enabling real-time virtualization. This technology partitions a single computer into multiple virtual machines. Some virtual machines can run hard real-time operating systems (RTOS) for critical tasks like motion control, while others run standard operating systems like Windows or Linux for non-time-critical functions such as the HMI.

It also makes systems more reliable and easier to maintain due to fewer hardware components and points of failure. Furthermore, it allows for greater flexibility, as control software and other applications are no longer tied to specific hardware and can be moved between computers or servers to optimize performance.

The acontis EC-Master is used in many manufacturing lines, Robots, Material handling, providing the required reliable high-speed, high-accuracy access to the EtherCAT control network in lithography, metrology and wafer handling.

Addressing Industrial Challenges with acontis Technologies

acontis offers advanced solutions to key industrial automation challenges through its hypervisor and EtherCAT technologies:

Real-time Responsiveness: acontis' hypervisor allows hard real-time and non-real-time systems to run on the same controller, enabling split-second decisions. EtherCAT ensures deterministic, ultra-fast data exchange for timely control.

Precision Control: EtherCAT provides low-latency communication for accurate motion control. The EC-Master Class-A package supports Distributed Clocks Master Synchronization for precise device coordination.

Diverse Integration: EtherCAT supports standard communication protocols, simplifying integration of diverse components. The EC-Engineer tool streamlines network configuration and reduces setup time.

Diagnostics and Troubleshooting: acontis offers powerful integrated diagnostic tools with features like error code libraries, automatic slave change detection, and advanced traffic monitoring, minimizing downtime and troubleshooting time.

Scalability: EtherCAT's flexible topology and features like Hot Connect allow scalable, dynamic device integration without reconfiguration, supporting evolving industrial needs.

Applications in Manufacturing that already profit from EtherCAT

The acontis EC-Master is used in many semiconductor machines, robots, PLC, high speed industrial machines, automation and motion controllers, providing the required reliable high-speed, high-accuracy access to the EtherCAT control network in lithography, metrology and wafer handling.

Real-World Applications of EtherCAT in Modern Manufacturing

As industries embrace smarter automation and faster production cycles, EtherCAT has emerged as a key enabler of precision, speed, and scalability. Below are manufacturing applications already benefiting from EtherCAT's real-time communication and control capabilities.

Robots normally have multi-axis robotic arms, which are used for complex tasks such as welding, assembly, and painting. EtherCAT enables real-time synchronization of motors and actuators, ensuring precise motion control even during high-speed operations. Its ability to integrate seamlessly with sensors and machine vision systems allows robots to make intelligent decisions on the fly, which is particularly important in automotive manufacturing and electronics assembly lines.

CNC machines are critical for high-speed milling, turning, and laser cutting, EtherCAT provides deterministic positioning and ultra-low latency control. These features are vital for achieving consistent part quality, especially in industries such as aerospace and precision engineering. The precise coordination of movements enabled by EtherCAT contributes to extended tool life and increased efficiency in mold and die making, where accuracy is non-negotiable.

Packaging Machines

This is another area where EtherCAT delivers significant advantages. These systems perform multiple coordinated tasks—sorting, filling, sealing, and labeling—at very high speeds. EtherCAT ensures fast cycle times and tight coordination among actuators, which is crucial for maintaining product throughput and packaging quality. Its flexibility also allows quick reconfiguration during product changeovers, making it ideal for industries like food and beverage, pharmaceuticals, and consumer goods where variety and hygiene standards must be balanced.

Semiconductor Equipment such as wafer handlers, lithography systems, and test platforms demand synchronization at the nanosecond level. EtherCAT supports ultra-precise motion profiles and high-speed data acquisition, which are necessary for producing semiconductors with minimal defects. Its low error rate and high throughput capabilities make it an integral part of cleanroom automation and advanced semiconductor fabs, where even microscopic variations can impact yield and performance.

Automated assembly lines also benefit extensively from EtherCAT, particularly systems involving conveyors, pick-and-place robots, and vision-guided assembly tools. The protocol allows unified control of a wide variety of devices, from sensors to actuators, with minimal latency. This enables manufacturers to reduce downtime and maintain consistent quality across long production cycles. Industries such as electronics, automotive, and household appliance manufacturing rely on this seamless integration to scale their operations efficiently while maintaining flexibility.

Enabling precision and speed for any use-case