Apollo Foods x RossOps Case Study

Apollo Foods x RossOps Case Study

July 2025 | 30 Day Pilot | AI Supercharges Knowledge Transfer at Shift Handover

Demonstrating how AI native tools can enhance team practices and unlock step-change improvements in knowledge sharing in an organisation.

Background & Company Information

Apollo Foods is a distinguished New Zealand beverage manufacturing company nestled in the picturesque Hawke's Bay region. Their product portfolio includes Picky (premium juices and smoothies), The Apple Press (export apple juice), and Boring® New Zealand oat milk made with local oats). They also provide contract manufacturing for select Dairy products.

Industry: Beverage Manufacturing

Location: Hastings, New Zealand

Operations: 25 people inc. 5 engineers; 3 shifts/day, 5 day weeks

The Challenge

Apollo Foods engineers' top focus is to maintain optimum operating conditions and solve problems quickly. However, like so many other factories, they face the hidden costs of knowledge fragmentation. When all original engineers from the 7-year-old facility left, the current team started from scratch with only 2 days of handover, forcing painful first-time troubleshoots and surprise breakdowns from undocumented practices and modifications. To support knowledge transfer, Apollo used a paper-based shift handover system with 30-minute overlaps three times daily.

Specific Challenges:

Scattered information: Time lost hunting through binders and correlating information across multiple messaging platforms.

Communication gaps: Manual completion at end-of-shift meant details were often missed due to poor handwriting or fatigue.

No historical insight: Inability to access past fixes or spot recurring patterns before they caused production disruption.

Isolated expertise: No way for experts to share their reasoning, forcing teams to relearn everything independently.

The Impact

The difference between a minor stop and a multi-hour breakdown often came down to having the right information. This directly impacted OEE and team morale, as engineers felt they were constantly fighting the same battles without the benefit of lessons learned.

For instance, a recent disruption to an assetʼs main compressed air supply caused by a corroded safety burst disc led to a 2am call-in, as the root cause was hidden inside pipework and not immediately apparent. Yet, with this newfound knowledge, the engineer would diagnose the issue in minutes instead of hours and avoid the callout altogether.

The Opportunity

Apollo saw a chance to improve. By capturing and organising the teamʼs knowledge in a more reliable way, they could reduce repeated issues, speed up troubleshooting, and enhance decision-making across all shifts.

The Solution

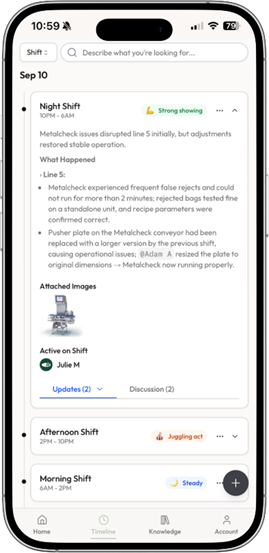

Real-time Input: Voice transcription, typing, images, and configurable tags form context-rich updates.

AI-powered Intelligence: Automatic shift summaries, and natural language querying and analytics across all data.

Knowledge Repository: Single source of truth for all machine documentation and procedures with intelligent querying.

Plug-and-play Setup: Complete configuration in under 1 hour, zero integrations required. Fits alongside existing software.

Data Migration: All 2025 historical handovers were processed into RossOps, providing immediate access to 6 months of institutional knowledge.

Compliance-ready: PDF export for each handover ensures zero data lock-in and regulatory compatibility.

"It exceeded my expectations. It exceeded all our expectations. I can tell you with certainty that if any of the guys were to leave to another company today, they would ask for a RossOps."

Jason Allen, Engineering Manager, Apollo Foods

Outcomes

In just under 30 days…

Faster Troubleshooting

When temporary overnight settings changes caused morning shift performance issues, the engineer queried RossOps, discovered the settings changes, and immediately reverted them – turning hours of unnecessary mechanical troubleshooting into 20 productive minutes + a thriving line.

Contractor Autonomy

As Jason noted: "We gave the extra phone to the contractor, showed him how it worked and off he went to record his work. We now benefit from his learnings whilst he requires less shadowing."

Proactive Issue Prevention

With just 30 days of data, RossOps can identify performance patterns and recurring equipment issues, track open problems, and flag missing mitigation measures to close the CI loop before failure reoccurs.

Instant Knowledge Access

Team members no longer waste time hunting for historical solutions, OEM contacts, and procedures. For newer members who don't know contacts like 'Steve from HBR', they simply ask RossOps. As Jason noted: "Engineer X didn't believe it until he tried it. Once he saw that RossOps could pull out anything he'd mentioned in the past, he knew he could trust it."

Accelerated Onboarding

The night shift engineer, being the latest hire, now has access to methods the team used previouslyto resolve issues he might face for the first time, accelerating his autonomy.

Key Learnings

AI-native setup enables rapid deployment - 1 hour vs months

Knowledge compounds rapidly - Insights emerge in just 30 days

Voice + AI removes language barrier for multi-cultural teams

Real-time capture beats end-of shift documentation

Adoption Metrics

61 shift handovers completed - consistent usage from day one across all shifts

3.2x increase in actionable content captured in 100% readable format

40,000 characters logged in one month - equivalent to a 300-page operational knowledge book by year-end

About RossOps

RossOps is a Swiss-Kiwi startup leveraging AI to create a "living, breathing factory brain" that captures and surfaces operational knowledge in real-time. RossOps uses AI to turn unstructured data into an automatically organised filing system that allows for capture, extraction & analysis.

Fully deployed in 45 minutes. Other industrial software typically takes weeks or even months.

Tiered subscription-based pricing. We provide maximum value when the whole team is involved, so no seat-based pricing.

Real ROI. It takes just one major breakdown resolved in 20 minutes instead of 5 hours to see immediate ROI.

Resources & Next Steps:

Or contact us directly at info@rossops.com to deploy RossOps at your site.